Knowledge Center

December 15, 2023

What is a Medical Washer Disinfector?

A Medical Washer/Disinfector is a medical device used for the automated cleaning of surgical instruments and work by combining impingement, water temperature, and detergent to clean heat-resistant and heat-sensitive devices.1

Are a Medical Washer and Washer/Disinfector the Same Thing?

No, washers and washer/disinfectors are not the same. While both devices are designed for cleaning and preparing medical instruments for patient use, they differ in their level of disinfection.

What Does a Medical Washer Do? |

What Does a Medical Disinfector Do? |

|---|---|

| A medical washer typically performs either no disinfection at all or low-level disinfection, which involves the removal of contaminants but does not achieve the same level of disinfection required for safe handling. | A Medical Washer/Disinfector provides intermediate disinfection, often called thermal disinfection. This disinfection helps clean and disinfect instruments, ensuring they are safe for handling during preparation and packaging for sterilization. |

Types of Medical Washer/Disinfectors Used In Healthcare

Single-Chamber Washer/Disinfectors

A single-chamber washer/disinfector cleans, decontaminates, disinfects, and dries many common reusable medical instruments that are not heat-sensitive and can be submerged in water. Single-chamber washer/disinfectors are the most common type of washers used in typical sterile processing departments. In larger facilities, it is common to see three to five (or more) washers lined up next to each other to deliver the throughput needed in sterile processing.

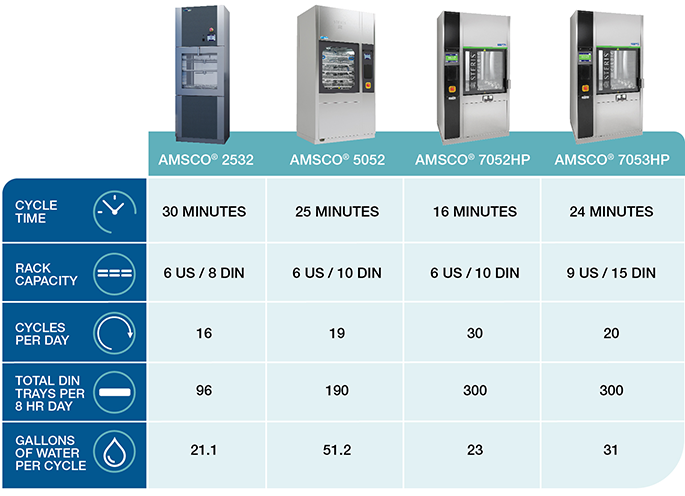

The AMSCO™ 7052/7053HP Washer/Disinfector can process reusable instruments in as little as 16 minutes and even delivers a validated process for the automated cleaning of select da Vinci® X/Xi EndoWrist® instruments*.

Multi-Chamber Washer/Disinfectors

Multi-chamber washer/disinfectors are designed for high-volume healthcare facilities. These machines consist of single-chamber washers linked together in a production line providing rapid instrument processing, with a rack exiting the chamber approximately every 10-12 minutes.

Multi-chamber washers are not common in hospitals, likely because if one chamber requires maintenance, the entire production line is affected.

Cart and Utensil Washer/Disinfectors

Cart washers are designed for cleaning and disinfecting larger items, including medical case carts, containers, and trays.

These large washers can process many items, including containers and loaner trays, using an optional instrument cycle.

Ultrasonic Washer/Disinfectors

Another common type of automated cleaning equipment is an Ultrasonic Washer. Ultrasonic washers and sonic irrigators provide automated cleaning using high-frequency sound waves to create microscopic bubbles in a cleaning solution that fully submerges devices. These bubbles implode, producing intense scrubbing action that effectively cleans intricate and delicate instruments. For more information on ultrasonic cleaning, view our Guide to Ultrasonics.

What are the 5 Stages of a Washer/Disinfector?

Each medical washer/disinfector typically goes through five phases:

-

Pre-Wash

The pre-wash phase involves wetting the instruments to help break the surface tension of soils on the instruments. -

Wash

During the wash phase, mechanical cleaning activity is introduced. Agitation and impingement physically remove contaminants from the instruments. Cleaning agents, including enzymatic and neutral solutions, are added to facilitate cleaning during this phase. Older washers have two wash phases. The first occurs when enzymatic detergent is added at one temperature, followed by the second when a wash occurs with neutral detergent at a different temperature. This requires the washer to be drained and refilled, adding cycle time and increasing water usage. Newer STERIS washers and chemistries, however, are designed to complete the washing phase without draining and refilling.

-

Rinse

The rinse phase removes residual cleaning agents and soils. This phase uses no chemistry, and the quality of rinse water may be critical, depending on the device manufacturer's instructions for use (IFU). At this stage, the devices are considered clean but not disinfected. -

Thermal Rinse

A thermal rinse is an additional phase that thermally disinfects the devices, rendering them safe to handle for department staff. This phase often uses treated water and may include the addition of lubricants to help hinged instruments move freely. -

Dry

The final phase, drying, uses a range of temperatures depending on the type of devices being processed. For example, plastic instruments require lower temperatures for longer durations, while stainless steel instruments can be dried faster at higher temperatures. Some drying systems incorporate HEPA filtration or dynamic drying systems that adjust cycle time based on the load's dryness.

What Medical Equipment is Processed in the Washer/Disinfector?

Washer/disinfectors process a wide range of reusable medical devices and equipment, including:

- Instruments: Surgical instruments, such as scalpels, forceps, and scissors

- Anesthesia and Respiratory Equipment: Breathing circuits, masks, and tubing

- Basins and Bowls: Used for various medical procedures

- Containers: Medical containers and sterilization trays

- Trays and Operator Room Shoe Covers: Essential items used in surgical and operating room settings

What Detergents Are Used in a Medical Washer/Disinfector?

Specialized detergents are used in washer/disinfectors, and their compatibility with medical devices and the machine is crucial. These detergents typically come in Enzymatic, Neutral, or Alkaline formulations developed to effectively remove soils and contaminants while ensuring the safety and integrity of the instruments.

Washer detergents work in tandem with the machine's cleaning process to deliver cleaning and disinfection. For example, Prolystica High Performance Instrument Cleaning Chemistries are formulated specifically for healthcare to deliver high-performance cleaning. With a low-foam profile and defoaming capabilities of protein soil, this cleaning chemistry helps washer/disinfector pumps and pressure efficiency, ensuring foam does not inhibit spray-arm performance.

Did you know?

STERIS has been designing and developing our washer/disinfectors and chemistries for more than 25 years. We design and produce these together and consider key factors in your process, from the medical devices to the equipment used to process these devices. We understand how instrument cleaning chemistries perform to remove a broad spectrum of soils from devices, but also how those cleaning chemistries need to work synergistically with washers to maximize their performance, all while protecting your devices and equipment.

What Does a Rinse Agent Do in a Medical Washer/Disinfector?

In the cart and utensil washers, rinse agents such as "Dry 'N Shine Concentrated Drying Agent" aid in the drying and rinsing case carts. They help prevent water spots and ensure the carts are thoroughly dried and ready for use.

Other Chemistries

In addition to detergents, other chemistries play an essential part in the washer/disinfector process:

- Instrument Lubricants: In instrument washers, lubricants are sometimes added during the rinse phase. These lubricants facilitate the free movement of instruments, ensuring they operate correctly and help extend their lifespan.

- Descalers: These are aggressive acidic solutions used to remove scale buildup due to poor water quality within the machine.

Medical Washer/Disinfector Maintenance

How Often Should a Medical Washer/Disinfector Be Serviced?

Proper maintenance of medical washer/disinfectors is crucial to ensure their reliability and effectiveness. When needed, routine maintenance, preventive checks, and service repairs are essential aspects of keeping these machines in optimal condition and should be performed by properly trained technicians. STERIS Equipment Services can assist medical facilities with routine, preventative, and emergency service needs with 24/7 technical support and a dedicated team of field technicians.

Routine Maintenance

Daily: Certain checks and maintenance tasks should be performed daily to ensure the washer/disinfector's proper functioning. This includes cleaning and inspecting critical components such as washer rack spray arms, drain components, and chemistry levels. Washer/disinfectors should also be tested each day that it is used to help ensure cleaning is done effectively, using a washer indicator test.

Weekly: Weekly maintenance tasks may include more thorough inspections and cleaning routines to check for any signs of wear or damage.

Check the operator manual of your specific washer/disinfector for a schedule of routine and preventive maintenance tasks.

The Importance of Preventive Maintenance

Preventive maintenance is critical to prevent unexpected downtime. Technicians should follow the manufacturer's maintenance manual and recommendations for specific washer models. Preventive maintenance helps identify and address issues before they become significant problems and helps ensure consistent performance.

How Often Should You Test Your Medical Washer/Disinfector?

Testing a medical washer/disinfector is critical to quality control. Mechanical cleaning equipment should be tested each day that it is used.

Methods of verification include directly testing individual instruments for residual soils, employing a test device that is a consistent and repeatable challenge to the cleaning effectiveness of the equipment, and monitoring critical parameters to evaluate the performance of the mechanical cleaning equipment. (ANSI/AAMI – ST79)

Washer Indicator Tests verify that the washer is functioning correctly by challenging it with indicator ink or soil. If all contaminants are removed, the test is considered passing. There are several benefits to using a cleaning indicator as a part of your process, the most important being the verification of key aspects of the automated cleaning process.

After automated cleaning, visual inspection remains an important step to ensuring cleanliness, but cleaning indicators like the VERIFY™ RESI-TEST™ Cleaning Indicators can provide additional assurance by detecting protein residues.

VERIFY™ All Clean Test Washer Indicator |

VERIFY™ RESI-TEST™ Cleaning Indicators |

|---|---|

Provides a consistent, reproducible method to routinely check the performance of your automated washer/disinfector process and instrument cleaning chemistry functionality to help ensure cleaning is done effectively. |

Detects the absence or presence of protein and protein residues with a sensitivity of ≥ 1μg. Cleaning verification is provided by collecting a sample from the device after manual or automated cleaning and before high level disinfection or sterilization. |

Considerations When Selecting a Medical Washer/Disinfector

Selecting the right medical washer/disinfector is crucial for ensuring your healthcare facility's instrument processing safety and efficiency. Some key considerations to keep in mind:

- Facility Needs and Volume - Ensure the selected machine can handle your facility's workload without causing delays.

- Types of Surgical Instruments – Some instruments require specific cleaning and disinfection processes. Ensure the washer/disinfector you choose can effectively clean and disinfect the range of instruments used in your facility.

- Automation and Efficiency - Consider whether you need automated loading and unloading and features like cycle time optimization and self-diagnostics.

- Maintenance and Service - Partnering with a manufacturer or service provider that offers prompt technical assistance, maintenance contracts, and replacement parts is essential for minimizing downtime and ensuring consistent performance.

- Total Cost of Ownership - This includes initial purchase costs, operating costs, maintenance expenses, and potential savings in labor and utilities.

- Training and User-Friendliness - A system reduces the risk of errors and improves overall efficiency.

By carefully considering these factors and conducting thorough research, you can select the most suitable washer/disinfector for your healthcare facility, ensuring the safety and efficiency of instrument processing operations. To learn more, read Key Considerations when Choosing a Washer/Disinfector.

Explore STERIS Washer/Disinfectors

* The RAS Racks are used in the RAS Cycle of the AMSCO 7052HP Single-Chamber Washer/Disinfector and the AMSCO 7053HP Single-Chamber Washer/Disinfector for the effective cleaning, rinsing, intermediate level disinfection and drying of reusable da Vinci® X/Xi and S/Si EndoWrist® instruments. da Vinci®, EndoWrist® are registered trademarks of Intuitive Surgical.