Knowledge Center

March 29, 2021

What are Surgical Instrument Detergents & Cleaning Chemistries?

Meticulous cleaning must precede any sterilization or high-level disinfection of these instruments. Failure to perform good cleaning can result in sterilization or disinfection failure, and outbreaks of infection can occur.”

– Centers for Disease Control and Prevention

Cleaning, which refers to the removal of soil from a medical device or instrument, is a critical step when processing instruments in the sterile processing department (SPD). As the name implies, instrument cleaning chemistries are solutions specifically formulated to aid in the removal of organic and inorganic soils from medical instruments and other devices used during patient procedures. These chemistries contain surfactants or chelating agents that help improve chemistry performance when cleaning these devices. Choosing the right instrument cleaning chemistry is key to successful manual and automated cleaning in healthcare facilities.

Types of Surgical Instrument Cleaning Chemistries

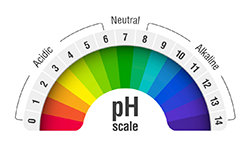

There are four types of cleaning chemistries primarily used on medical devices: enzymatic, neutral, alkaline, and specialty chemistries such as de-scalers that remove scale deposits to restore instruments. The first three are the most commonly used and are based on chemistry composition and pH. Enzymatic and Neutral detergents have a neutral pH around 7, while alkaline chemistries have a pH around 11.

Enzymatic Detergents

Instrument Cleaning Chemistries for

Manual Cleaning at the Sink

Enzymatic chemistries, like Prolystica HP Enzymatic Cleaner use enzymes to create a chemical reaction breaking down soils into smaller molecules so they can be easily removed and washed away. Manufacturers of enzymatic cleaners use different types of enzymes in their formulations which may include protease and/or lipase.

Enzymatic cleaners have a neutral pH and are highly effective at removing organic soils. In the SPD, enzymatic cleaners are used at the sink during manual cleaning, and again in the washer/disinfector during automated cleaning.

pH Neutral Detergents

Neutral detergents are neither acidic, nor alkaline, and offer the broadest material compatibility for instrument cleaning chemistries. These chemistries use specialized surfactants to aid in the removal of soils. Neutral chemistries like Prolystica HP Neutral Automated Detergent are generally only used in automated cleaning (including ultrasonic cleaners and washer/disinfectants) usually following the use of an enzymatic cleaner at the sink and/or the first phase in an automated washer. Neutral detergents are not as effective in hard water.

Instrument Cleaning Chemistries for

Automated Cleaning in a Washer/Disinfector

Alkaline Detergents

Alkaline chemistries can break down a wide range of soils and are effective in hard water that has a water hardness between 200 and 400 ppm. Because of their high pH, these detergents have some limitations in respect to material compatibility. These chemistries have poor compatibility with softer metals like aluminum and are generally only used in automated washing applications.

Specialty Chemistries

Beyond the three primary types of chemistries used in cleaning of medical devices, there are specialty chemistries you'll find specifically in SPD including:

- Point-Of-Use Chemistries used immediately after a procedure to prevent the drying of soils to aid the manual cleaning process.

- Instrument Lubricants to help ensure proper function and free movement of hinged instruments.

- De-Scaling Chemistries that remove stains and scale deposits on instruments and washer/disinfectors. Some of these chemistries even help restore the passive layer on stainless steel.

Benefits of High Performance Instrument Cleaning Chemistries

Using High Performance (HP) instrument chemistries goes beyond just effective cleaning and restoring/protecting instruments. For example, Prolystica® HP Chemistries are formulated to have the lowest foam profile plus will defoam protein soils that will create foam during the cleaning process.

Why does foaming matter? Minimizing foam in a washer/disinfector will maximize spray arm performance and physical soil removal while maintaining pump pressure. Overall, this helps to reduce cycle aborts and possible related service costs.

HP chemistries also increase efficiency at the sink with formulations that clean faster*, rinse better and most importantly improve visibility in the sink while cleaning. Compare the difference at the sink between standard and high performance chemistries:

Standard Cleaning Chemistry

Enhanced Visibility at the Sink with Prolystica High Performance Chemistry

How to Select the Right Cleaning Chemistry

Some of the most important considerations when choosing a cleaning chemistry are:

Common Soil Types

Understanding your facility's typical procedures will help determine the appropriate chemistry based on your needs. General surgeries expose instruments to a range of organic and inorganic soils and the correct selection of an enzymatic detergent, such as a dual-protease enzyme formula, can effectively target all soils.

Instruments Processed

Material compatibility with chemistries varies. Aluminum and plastics react differently to certain chemistries when compared to stainless steel instruments. Understanding what materials, and what devices you are processing can aid in the selection of chemistry. For example, it is recommended to not use an enzymatic chemistry on eye instruments.

Water Quality

While sometimes overlooked, water is the most damaging threat to delicate surgical instruments and the quality of your water plays an important role in the effectiveness of your cleaning chemistry. Chemistry and water work together to facilitate cleaning, but even the highest quality water can damage instruments or even washer/disinfectors.

Water contains minerals, ions and other impurities that will lead to pitting, discoloration, rust and other damage. Using a high performance chemistry like Prolystica allows your chemistry to counteract the damaging effects of water and prevent damage to instruments by ensuring those harmful deposits are not left on your instruments.

To determine your water quality, it is important to use a skilled lab that understands instrument reprocessing to properly analyze your specific water quality. STERIS provides a full-service laboratory and water testing service through our Diagnostic Solution Service to analyze your water quality throughout critical steps in the reprocessing loop.

There is much more to an instrument cleaning chemistry than just its cleaning properties. SPDs will use combinations of chemistries in the cleaning process to take advantage of the various benefits of each. Using a high performance chemistry with the correct formulation provides enhanced benefits beyond cleaning. Below are the general qualities to review when selecting the right chemistry for your facility:

| Ideal Features for all Instrument Cleaning Chemistries |

The High Performance Difference |

|---|---|

|

Ideal Features of Standard Chemistries PLUS HP Chemistries defoam protein soils that naturally occur in the cleaning process, increasing washer efficiency. Specific manual enzyme formula increases visibility during manual cleaning so technicians see submerged sharps and can better see what they are doing. |

Related Products

*See Technical Data Monograph for Prolystica® HP Enzymatic Manual Cleaner