Knowledge Center

March 31, 2023

.png?h=200&w=250&hash=A25B583C29B1504EFF0110CDDE474182)

Sizing Up Your Ultrasonic Needs for Device Processing

Ultrasonic cleaning systems provide an automated solution for delicate or highly intricate medical devices.

To perform ultrasonic cleaning, an ultrasonic washer uses a cleaning solution, cavitation, and flushing action to thoroughly clean complex surgical instruments. Common devices processed in ultrasonic cleaners include Minimally Invasive Surgical (MIS) instruments, ophthalmic instruments, and laparoscopic devices such as robotic surgical instruments.

Want to Learn More about How Ultrasonic Washers Work?

View our Guide to Ultrasonic Cleaning

Ensuring you have the right ultrasonic washer to support your facility's device inventory and throughput needs is important. Many high-growth procedures, such as orthopedic and ophthalmic require more complex instruments. Facilities, including Acute Care and Ambulatory Surgery Centers (ASCs), should evaluate their current needs and capabilities with plans to support future reprocessing needs.

There are three critical questions to help you select the right ultrasonic washer for your facility:

- Quantity – How many devices are you reprocessing on a typical day?

- Type – What devices are you reprocessing?

- Space – How much space is available for an ultrasonic in your department?

How many Medical Devices will you be Reprocessing

It may seem obvious, but beyond the types of instruments, it is important also to consider the volume of devices requiring sonic cleaning.

- How many devices do you need to process using ultrasonic cleaning per day to keep your Sterile Processing Department (SPD) running at high efficiency?

- How long does a typical cycle take per the medical devices' Instructions For Use (IFUs)?

- Based on your answers to these questions: what ultrasonic throughput is needed to support your reprocessing needs?

- Also, consider: Do you need a dedicated ultrasonic for eye instruments?

To ensure maximum throughput and staff productivity, your ultrasonic washer must be able to process the maximum number of devices in a minimum number of cycles to meet the needs of a growing caseload. You will need to consider what your volume looks like in the near term, perhaps over the next 3-5 years. With minimally invasive surgical procedures rapidly growing, SPDs will rely on ultrasonic cleaning to process more medical devices that may require a faster turnaround.

Many ultrasonics can process a variety of devices, including orthopedics, eye instruments, or robotics. Always check the manufacturer's load capacity recommendations and device IFUs for sizing and compatibility. The chart below compares device type and capacity capabilities.

|

Tabletop ultrasonic irrigator Processes up to 12 lumens or 11 lbs. of instruments per cycle |

Large freestanding ultrasonic cleaner Processes up to 16 lumened devices, or up to 35 lbs. per cycle* |

Smaller footprint ultrasonic washer Processes 20 lumened instruments, or up to 44 lbs. in every cycle |

Maximum capacity ultrasonic washer Processes 60 lumened instruments, or up to 66 lbs. in every cycle |

| — | — | Meets all robotic instrument IFU requirements with the automated wash, flush, and rinse cycles | Meets all robotic instrument IFU requirements with the automated wash, flush, and rinse cycles |

| *Unity 15 = 25 lbs. per cycle / Unity 20 = 35 lbs. per cycle | |||

What Devices are you Reprocessing?

It is important to consider the caseloads and associated sets you will be processing from the Operating Room (OR)

If your facility is experiencing a growing number of orthopedic procedures, a larger sonic to reprocess more devices in a single cycle will help address increasing demand.

Many surgical procedures that are growing in volume use lumened devices, which often are longer and will not fit in a smaller ultrasonic unit.

If you are processing robotic instruments, a sonic that meets all robotic instrument IFU requirements, including the automated wash, flush, and rinse cycles, would be best to optimize your workflow.

Do you need to process eye surgical instruments?

Unlike most instruments processed in an ultrasonic cleaner, eye instruments require a dedicated wash cycle free from enzymatic detergents. Based on this requirement, many facilities will have a dedicated ultrasonic washer strictly used for reprocessing eye instruments.

If you do not have a sonic dedicated additional cleaning and flushing of the entire sonic bay is required. This process helps ensure the removal of all enzymatic substances.

How much space is available for an ultrasonic washer in your department?

With a better understanding of the device types and procedure volume, space becomes the final consideration in choosing the right ultrasonic. Most hospital SPDs require larger, freestanding ultrasonic units based on device inventory and the volume of instruments they are reprocessing.

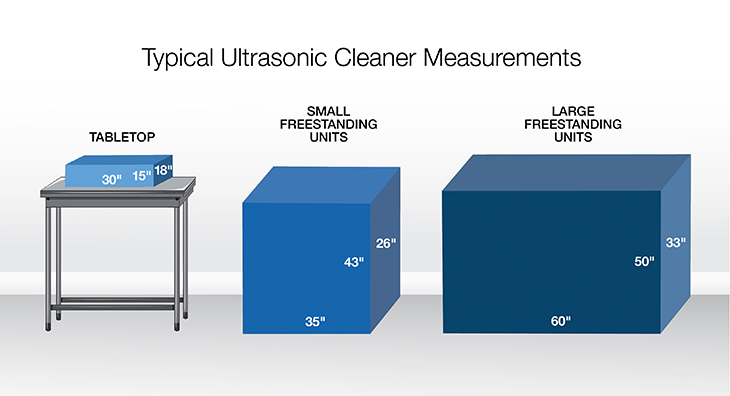

Regardless of which ultrasonic unit you may need, each unit must have at least 6 inches of clearance on each side for servicing. To aid in your decision, the example below illustrates and compares typical ultrasonic dimensions:

Which ultrasonic is best for you?

The right ultrasonic washer supports the necessary productivity required in your SPD. High-quality cleaning is critical when it comes to efficiency and ensuring compliance. Backlogs in decontamination can often result in delays and sometimes even canceled procedures.

Choosing the right ultrasonic surgical instrument cleaner for your facility today, and with an eye to the future, will enhance your department's throughput and productivity. By answering the questions in this article, you can confidently choose the right ultrasonic washer for your healthcare facility.