Knowledge Center

October 23, 2020

The Ultimate Guide to Surgical Instrument Cleaning Brushes

Using the right tool for the job is important, and one of the keys to effective cleaning is having the right instrument cleaning brush. This article will review how to choose the correct size and style of a cleaning brush from the common styles available.

Using the right tool for the job is important, and one of the keys to effective cleaning is having the right instrument cleaning brush. This article will review how to choose the correct size and style of a cleaning brush from the common styles available.Cleaning brushes used in healthcare are designed specifically to remove soils from often delicate instruments/devices used during surgical procedures. Soils can range from easy to wipe off blood or mucus, to harder to remove bone chips or burnt on surgical lubricants.

Choosing the right surgical cleaning brushes

Depending on the instrument/device you are cleaning, the brush you need may vary. There isn't a one-size-fits-all solution for manual cleaning, so the first step is to understand what you're cleaning. There are specific brushes designed to do specific tasks, and improper brush selection may lead to challenges for patients and providers including infections or instrument/device damage. Brush types include general, toothbrush, burr, channel, valve, and acetabular reamer brushes, to name a few.

Channel Cleaning Brushes

When cleaning lumened instruments/devices, you need to be able to clean the interior and exterior of the device. Channel style brushes support effective cleaning inside lumened instruments/devices, letting you guide the brush through the lumen while the bristles dislodge bioburden from hard-to-reach interior channels. Channel Cleaning Brushes are available in standard, acrylic or fan tip, flexible, heavy-duty, tapered, looped end, curved, and reusable handle channel brush options for your specific cleaning needs.

Standard Channel Brushes

Fan Tip vs. Acrylic Tip

Channel Cleaning Brushes

Fan Tip brushes are specifically designed to clean the distal end of a close-ended lumen

Acrylic Tip brushes provide an extra level of protection against internal lumen scratching

For most basic lumened instruments/devices, standard channel brushes are effective at removing soils from the interior of the device. This is the most common channel style brush; ranging in size from 7 to more than 50 inches in length, with a variety of diameters available to fit your reprocessing needs.

Fan Tip Channel Brushes

Fan tip channel brushes have fanned bristles to help reach the ends of closed lumened instruments/devices.

Acrylic Channel Brushes

Similar to fan tip channel brushes, acrylic-tipped channel brushes provide an added level of safety against potentially scratching the instrument/device. This type of brush is commonly used on laparoscopic suction tubes or any straight lumened item.

Flexible & Curved Shaft Channel Brushes

Flexible brushes let you guide through angles and bends of suction tubes and reach the ends of open and closed-ended instruments/devices with an extended 25-inch length. Curved shaft brushes are already bent into a curve, while flexible channel brushes feature kink-free shafts and pull-through ability.

Heavy Duty, Polypropylene Channel Brushes are

Chemically Resistant to Bacterial Growth.

Heavy-Duty Channel Style Brushes

When maximum control is needed to effectively clean your most difficult lumened instruments/devices, such as scope ports, heavy-duty channel brushes are the right choice. Adding more protection, polypropylene brushes use chemically resistant, synthetic filament materials providing the bristles resistance to bacterial growth.

Tapered Channel Style Brushes

The tapered channel style brush offers a twisted wire-end design to ensure all parts of narrow tapered lumens can be reached.

General Cleaning Brushes

All Purpose Instrument Cleaning Brush

The Sterile Processing Department (SPD) doesn't only clean delicate surgical instruments/devices. General/all-purpose instrument cleaning brushes help address larger surfaces on items including bowls, and basins.

Toothbrush Style Cleaning Brush

Easily the most popular general instrument cleaning brush, the toothbrush cleaning brush offers single and double-ended options and is the "jack of all trades" when it comes to handling instrument/device exteriors including forceps, retractors, and box locks. The bristles can be metal or nylon and are designed for effective cleaning, with nylon being used on fine surfaces of delicate instruments/devices.

Valve & Port Cleaning Brush

A specialized brush is recommended for cleaning the valves and ports of instruments/devices. Used most often for cannulas, the valve brush lets you exercise the control gained by using a shorter brush length.

Reamer Cleaning Brush

Bone reamers are unique orthopedic instruments that require specialized cleaning. Using a reamer cleaning brush provides control and maximum cleaning coverage during manual cleaning.

Burr Cleaning Brush

The difference is the handle — burr brushes are built to withstand a high amount of force during manual cleaning. Unlike toothbrush style, the plastic used in a burr brush is extremely resistant to breaking/cracking under pressure.

Pipe Cleaner Brush

After cleaning, devices should be dry before being packaged for sterilization. Pipe cleaner brushes can help wick away moisture.

Selecting the Right Brush Size For your Medical Device

Choosing the right size and right brush is key to successful surgical instrument/device cleaning.

“When decontaminating devices with lumens, personnel should soak and flush the lumen according to the manufacturer's written instructions for use...brush the lumen with a brush that is the correct size (diameter and length) and bristle type and material for the lumen, then rinse it.” ANSI/AAMI ST79: 2017, section 7.6.2

How do you know what size brush is correct for your instrument/device?

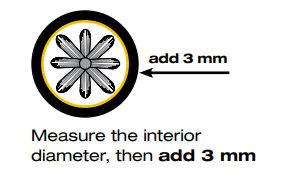

There are several tools available to confirm the correct brush size for your instrument/device, and knowing the right size is important when choosing a channel style brush.

Choosing the Right Fit

Too Small

Bristles will not make sufficient contact and surfaces may go untouched

Too Large

Applies unnecessary pressure on bristles and may cause brush to get stuck in device

JUST RIGHT

Bristles make sufficient contact with the instrument

French Catheter Scale (PR450003)

French Catheter Scale/Brush Gauge

(STERIS Part Number PR450003)

Tools like a French catheter scale offer a convenient way to determine the instrument/device diameter and help you select the most appropriate brush size for your needs. Using a tool like this, determine the diameter of your device then add 3mm: this is the ideal channel style brush you will need.

To know what length of brush you need, take the total length of the channel you are cleaning and add 5cm. This is the minimum length brush you should use, but you may end up using a longer one if that's what is currently available. The key is to not to use too short a brush.

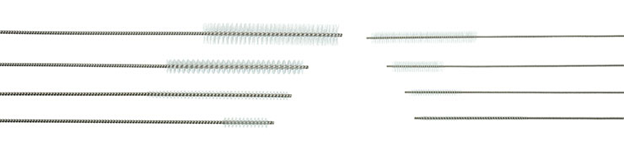

When Should I Replace Instrument Brushes?

Brushes should only be used to reprocess a single instrument/device set. While brushes can be single use/disposable, some facilities may choose to clean, decontaminate, and reuse their instrument cleaning brushes.

What Do the Standards Say?

“Reusable brushes should be cleaned and decontaminated at least daily or when heavily soiled. Brushes that show wear should be discarded.” Standards of Practice for the Decontamination of Surgical Instruments, Association of Surgical Technologists.

“Brushes used for decontamination need to be cleaned themselves and disinfected or sterilized. Brushes that show wear will not clean thoroughly. Prompt cleaning of brushes and other cleaning implements reduces or eliminates biofilm-forming microorganisms and thus minimizes the formation of biofilm.” ANSI/AAMI ST79:2017, section 7.4.1

The standards followed by Sterile Processing Departments don't specifically say when a brush should be replaced. So how can a facility determine that a brush is “worn” or “damaged”?

Inspect brushes for:

- Wear and tear

- Damaged bristles

- Bristles that are falling out, or missing

- Bristles that are left over in/on instruments

- Residual soil on brush after washing

- Bends or twists in the brush handle or shaft (Channel Brushes)

Ineffective removal of soils and biofilms may result in patient harm or damage to instruments/devices. Having the right brush for the instrument/device you are processing will help optimize your cleaning process and ensure effective cleaning. When a brush is damaged, broken bristles or stems left behind in the instrument/device can cause costly repairs or damage, as well as additional time for re-cleaning instruments/devices.

Explore STERIS Instrument Cleaning Brushes

Shop for the Products Featured in this Article

Knowledge Center Category List

| FOLLOW US | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|